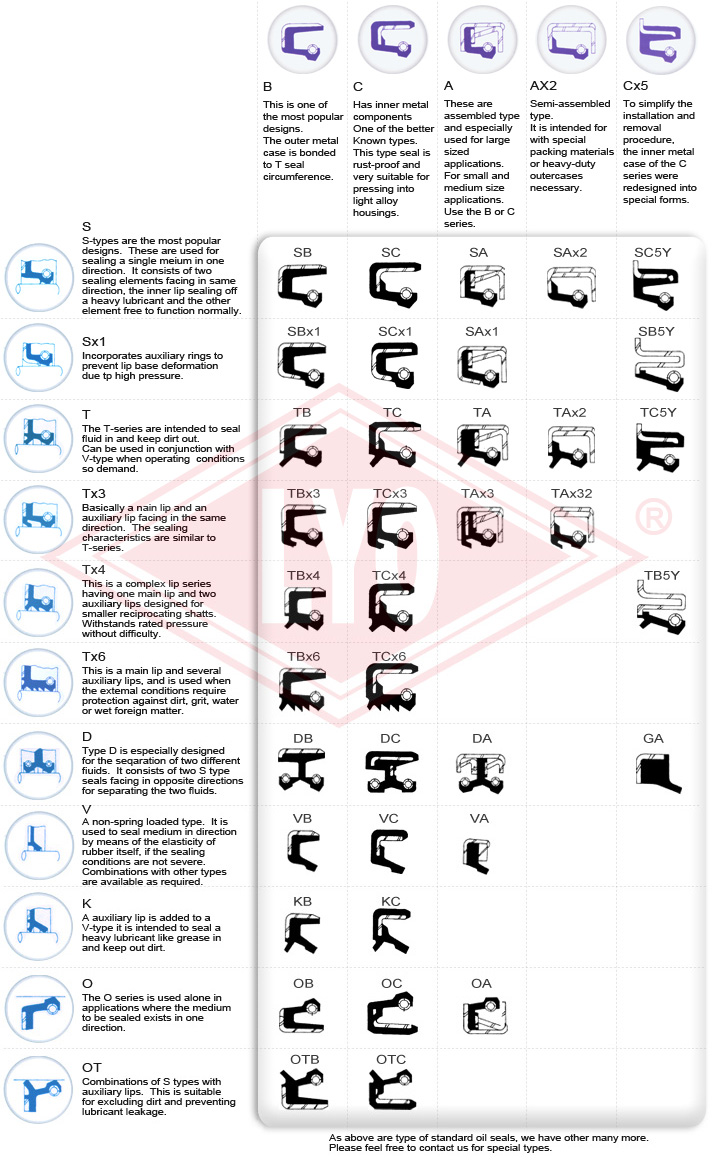

The selection of the proper oil seal for a given sealing application is governed by the operating conditions under which the seal must function. To assist you in this selection, the following pages explain the conditions and limitations for which LYO seals are designed.

One of the most popular designs, the seal, O.D. and the housing bore are pressfitted. The sealing function is accomplished by the sliding surface contact of the seal lip the shaft. a close lip shaft. a close-coiled helical spring is used.

Oil seals are pressfitted onto a shaft, the lip and housing bore have a sliding surface contact. Used only for specific applications where shaft seals are not easily installed. Pitchcoiled springs are used on this type.

RUBBER TO METAL BONDING

RUBBER SEALS

MODED RUBBER

GASKETS

TEFLON PARTS